Online monitoring system of oxygen content in reactor

Product model:TINSA-CT-100

Product overview

During the nitrogen filling protection process of the reactor, it must strictly ensure that the reactor is in an oxygen free state, and the oxygen content shall be controlled within 1% vol; It puts forward higher requirements for the service life, accuracy and response time of the sensor.

Technical parameter

| Model | TINSA-CT-100 |

| Measuring range | 0~1000/10000ppm |

| Detection principle | electrochemistry |

| Check the accuracy | 1PPm / 0.01%VOL |

| Explosion proof grade | ExdibIICT6Gb |

| Degree of protection | IP67 |

| Range switching | PPm-VOL Free conversion |

Application area

Reactor nitrogen filling protection system

Nitrogen filling protection in various processes

Tank nitrogen filling protection system

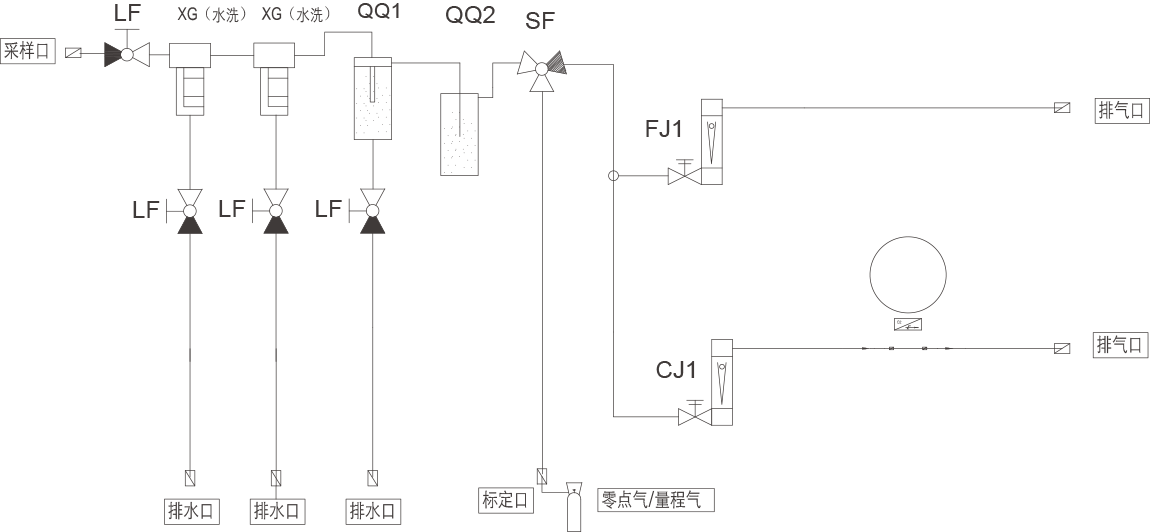

System composition

Product features

Customized pretreatment

Conduct back blowing, acid-base neutralization, organic matter removal, water removal, cooling, drying, pressure stabilization, constant current, etc. for the sample gas

Security

If the oxygen concentration value exceeds the level-1 preset alarm value, the electromagnetic regulating nitrogen charging replacement will be automatically started until the value is reduced to the safe range

Nitrogen flow control

The nitrogen control box is equipped to automatically cut off the large flow when the oxygen concentration value is within the safe range, so as to realize the continuous supply of small flow and meet the micro positive pressure in the kettle machine

Applicable to explosion-proof area

Intrinsically safe and explosion-proof composite instrument, which can meet the severe use area

Signal acquisition

16 bit ADC digital to analog conversion to meet the micro oxygen data acquisition, with higher accuracy

Module platform

The pretreatment stages and functions can be freely adjusted according to the actual use, and the application range is wider

Easy maintenance

One click calibration / calibration, tool free disassembly and maintenance, hot plug and replacement of sensor components

Intelligent display

Self luminous OLED display, wide viewing range from multiple angles

Application case

Download materials

Home

Company profile

System

Online monitoring system for oxygen content of centrifuge

News

Contact

Leyu town (Lefeng Road) Industrial Park, Zhangjiagang City, Jiangsu Province

Website